Service 1

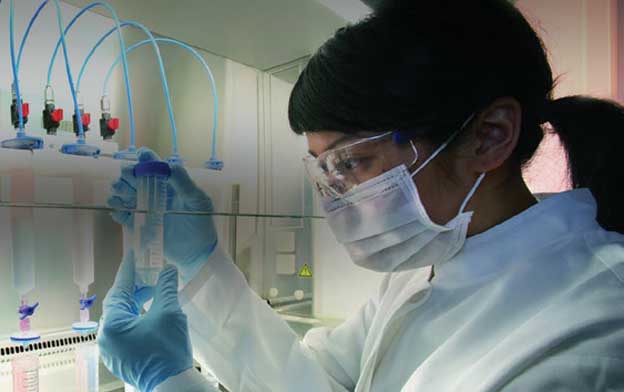

Testing for Oil Conditioning Monitoring (OCM)

Predictive maintenance systems based on oil condition monitoring (OCM) tests assist clients in avoiding costly equipment, engine, and power-train breakdowns. OCM tests from Foxer Lubricants evaluate engine oils, lubricating oils, and other fluids to identify lubricant engine wear, lubricant quality degradation, and other issues. Foxer Lubricants laboratories monitor oil condition to safeguard our clients’ high-value equipment, engines, and other systems, avoiding costly downtime.

Oil Condition Monitoring Tests Can Provide Early Detection of:

Additional variables that might cause machinery damage or failure prematurely

- Testing for Oil Wear Contamination

- Water content

- Insoluble content, engine wear detritus

- Additive elements

- Additional variables that might cause machinery damage or failure prematurely

- Wear Metals Testing